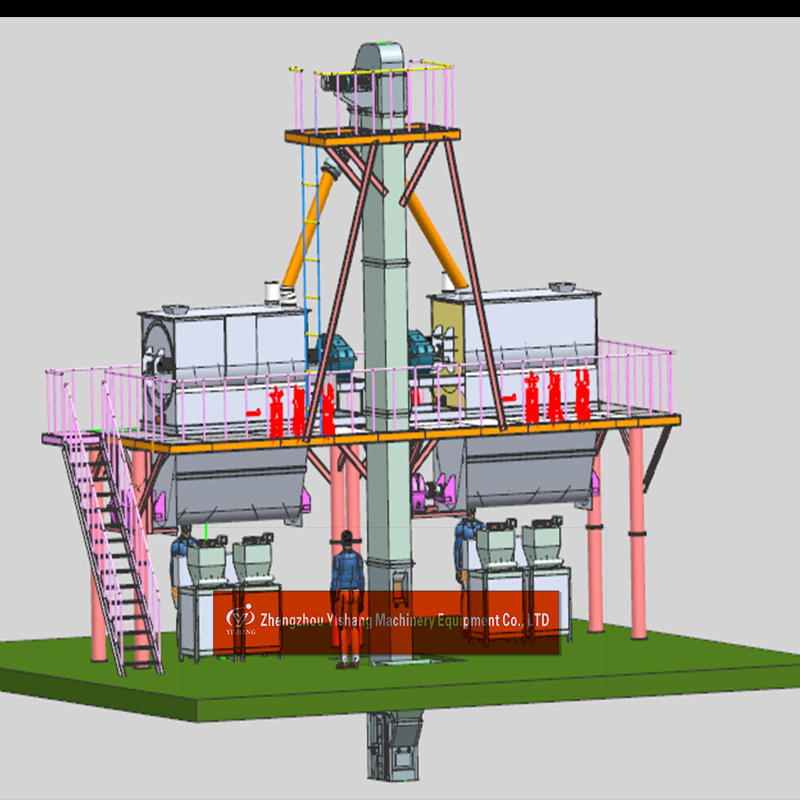

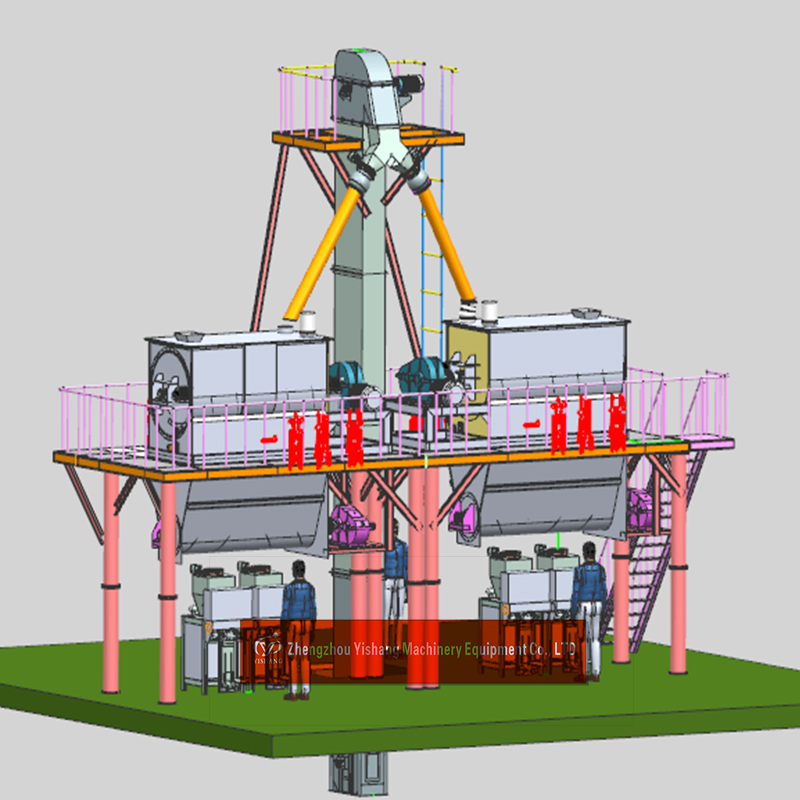

Maintenance Manual for Thermoplastic Road Marking Paint Manufacturing Equipment

2025-06-12

2025-06-12

Thermoplastic road marking paint manufacturing equipment is essential for producing durable, high-visibility road markings. Proper maintenance ensures longevity, efficiency, and consistent product quality. This manual provides clear, step-by-step guidelines for maintaining yourthermoplastic Road Marking Paint production machinery.

Check for oil leaks in hydraulic systems.

Inspect electrical connections for wear or damage.

Ensure mixing blades and agitators are free from hardened thermoplastic residue.

Verify that temperature controls are functioning correctly.

Clean the mixing tank and discharge valves to prevent material buildup.

Flush the system with a compatible cleaning agent if switching between different thermoplastic formulations.

Wipe down control panels and exterior surfaces to prevent dust accumulation.

Apply high-temperature grease to bearings, gears, and chains.

Check hydraulic oil levels and top up if necessary.

Examine heating coils and thermocouples for signs of wear or corrosion.

Calibrate temperature sensors to ensure accurate readings.

Inspect drive belts for tension and wear; replace if cracked or loose.

Listen for unusual noises in motors and gearboxes, indicating potential issues.

Disassemble and manually clean mixing paddles and shafts.

Use a high-pressure washer (if applicable) to remove stubborn deposits.

Tighten loose wiring connections.

Test emergency stop buttons and safety interlocks.

Replace air and oil filters to prevent contamination.

Conduct a thorough examination of all mechanical and electrical components.

Replace worn-out parts such as seals, gaskets, and heating elements.

Recalibrate temperature, pressure, and speed controls for optimal performance.

Inspect the frame and support structures for cracks or corrosion.

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven Mixing | Worn blades or incorrect speed | Replace blades or adjust agitator speed |

| Overheating | Faulty thermostat or blocked vents | Replace thermostat, clean cooling fans |

| Leakage | Damaged seals or loose fittings | Tighten connections or replace seals |

Always shut down and disconnect power before maintenance.

Wear heat-resistant gloves and safety goggles when handling hot components.

Follow lockout/tagout (LOTO) procedures during repairs.

Regular maintenance of thermoplastic road marking paint manufacturing equipment ensures smooth operation, reduces downtime, and extends machine life. Follow this guide to keep your production line running efficiently.

For further assistance, contact our support team at +8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com