Zhengzhou Yishang Machinery Unveils Next-Gen Dry Mortar Production Line: Precision, Efficiency, and Sustainability

2025-06-21

2025-06-21

Smart Manufacturing Breakthrough: How Yishang’s Automated Dry Mortar Production LineSystem Redefines Construction Efficiency

Zhengzhou, China – In a bold move to revolutionize the construction materials industry, Zhengzhou Yishang Machinery Co., Ltd. has launched its state-of-the-art fully automated dry mortar production line, setting new benchmarks for speed, accuracy, and eco-friendly manufacturing.

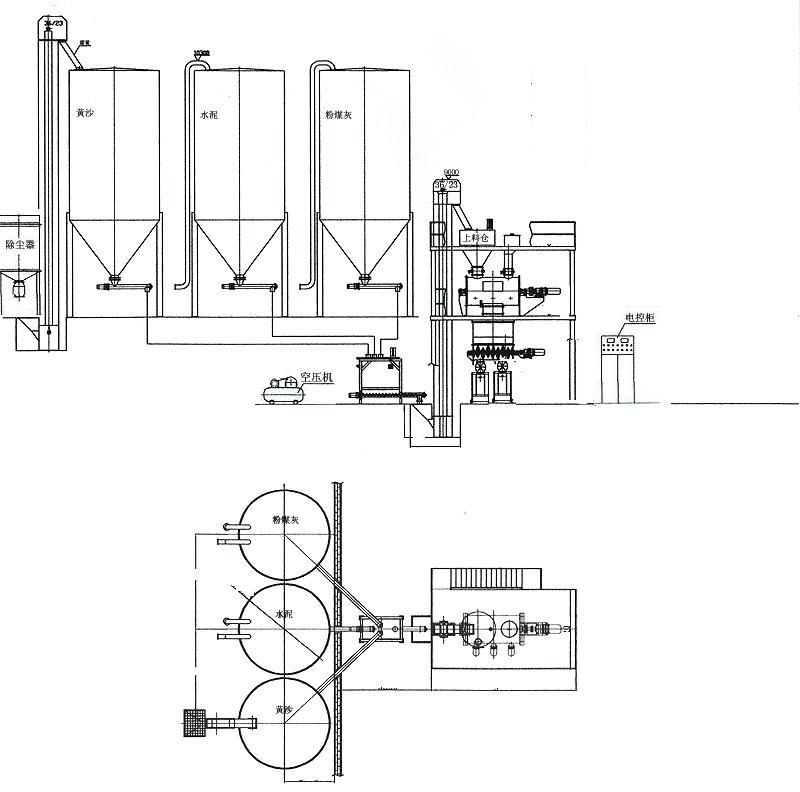

Process Flow Description of Dry-mixed Mortar Production Line

The dry mortar production line mainly consists of storage tanks, double-shaft non-gravity mixers, elevators, pre-mixing bins, small material bins, finished product bins, packaging scales, bucket elevators, dust collectors, fully automatic metering and batching scales, frames, etc. The storage tank is mainly used for storing raw materials, with a general capacity of 60 cubic meters and a quantity of 3. It is used to store materials such as cement, fly ash, and sand. During production, according to the customer's formula, cement, fly ash, and sand are proportionally conveyed to the batching scale bin. Then, the batching scale bin delivers the prepared materials to the bucket elevator. Small proportions of valuable masterbatches such as cellulose and rubber powder can be measured by electronic scales and put into the admixture hopper. The materials are lifted to the mixing bin on the frame by the bucket elevator to wait for mixing. Then, the materials are discharged into the double-shaft non-gravity mixer for mixing. The mixed materials enter the finished product bin through the pneumatic door and are packaged by the valve port packaging machine to complete the operation. It is an advanced step compared with the simple production line.

Yishang’s advanced system integrates cutting-edge technology to streamline production:

🔹 Smart Storage & Batching

Three 60m³ storage silos hold bulk materials (cement, fly ash, sand).

An AI-powered batching system precisely measures ingredients based on custom formulas, eliminating human error.

🔹 High-Speed Mixing & Additive Precision

A dual-shaft gravity-free mixer ensures ultra-homogeneous blending in seconds.

Critical additives (cellulose, polymer powder) are weighed via high-sensitivity electronic scales for flawless consistency.

🔹 Dust-Free, Energy-Efficient Operation

Built-in pulse jet dust collectors reduce emissions by 99%, complying with global environmental standards.

Automated valve bagging speeds up packaging while minimizing waste.

✅ 50% Faster Production – No manual handling, no downtime.

✅ Zero Material Waste – Exact (formula) control maximizes cost efficiency.

✅ Plug-and-Play Automation – Easy to operate, minimal training required.

Ready to upgrade? Visit www.drymortarmachinery.com or contact sales today!+8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com