Case Study: Zhengzhou Yishang Machinery's Tailored Solution for Space & Budget-Constrained Dry Mortar Production Line

2025-12-16

2025-12-16

Client Profile: A regional building materials startup, aiming to enter the dry-mix mortar market (focusing on tile adhesives and plaster). Their primary constraints were a low-ceiling workshop (clear height: 4.5 meters) and strict initial investment limits, which made standard modular plant designs infeasible.

Challenge: Conventional dry mortar lines require significant vertical height for gravity-fed sequencing (e.g., tall silos, elevated mixers, overhead conveyors). High-capacity ribbon mixers or twin-shaft mixers also demand substantial investment. The client needed a compact, low-investment, yet efficient and scalable production line capable of producing 5-8 tons per hour of quality product.

Yishang's Engineered Solution: The Horizontal Compact Modular Line

Instead of a vertical layout, our engineers proposed and implemented a revolutionary horizontal, single-level process flow, eliminating height dependency. The core innovation was the integration of a Space-Optimized, Enhanced Horizontal Ribbon Blender with a Pre-Mix & Micro-Dosing Module.

Key Design & Component Breakdown:

Low-Profile Silo Cluster & Segregated Micro Ingredient Batching:

Two flat-bottom cement & filler silos (side-by-side) with low-height screw conveyors feeding directly into the ribbon blender.

A separate, enclosed micro-additive dosing station equipped with high-precision loss-in-weight feeders for cellulose ether, redispersible polymer powder (RDP), and other functional additives. This prevented segregation and ensured accurate, low-quantity dosing.

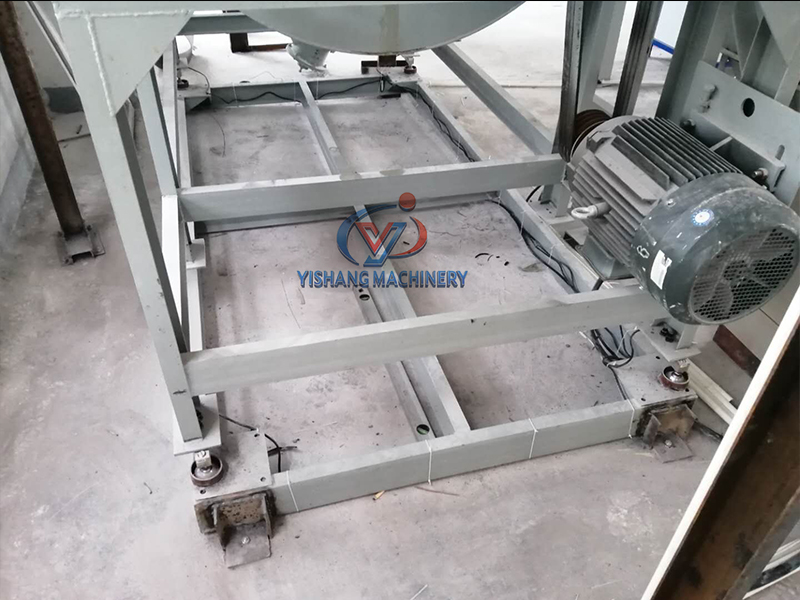

Core: Customized Horizontal Ribbon mixier:

A specially designed ribbon mixer was used. Its first 1/3 section acted as a pre-dispersing and liquid addition zone, where powders pre-mixed and liquid additives (via high-pressure spray nozzles) were introduced.

The remaining length ensured homogeneous high-shear blending, achieving uniformity comparable to more expensive mixers but at a lower cost and height. Variable Frequency Drive (VFD) control allowed optimized mixing cycles for different recipes.

Compact Packing & Material Handling:

The blended mortar discharged directly onto a short shuttle conveyor feeding a dual-outlet valve bag packer (or Big Bag station), chosen for its reliability and lower cost vs. full valve packers.

A miniature, bucket elevator (specifically designed for low headroom) lifted finished bags to a small platform for palletizing, utilizing the minimal available vertical space efficiently.

Results & Client Value:

Space Solved: The entire line fits within a 4.5-meter height, operating on a single floor plan.

Cost Solved: Investment was reduced by approximately 35% compared to a standard vertical modular plant of similar output, with lower civil work costs.

Quality Achieved: Precise micro-dosing and the enhanced mixing design ensured product quality met GB/T 25181 and EN 13888 standards for target applications.

Future-Proofed: The design allows for modular expansion—adding parallel blenders or packing lines as demand grows.

Conclusion:

This case demonstrates Zhengzhou Yishang Machinery's core competency: designing problem-specific, non-standard dry mortar equipment solutions. By moving from a vertical to a horizontal paradigm and re-engineering the mixing process, we turned severe client constraints—low workshop height and limited budget—into a functional, efficient, and profitable production asset. We specialize in customized, compact dry mix plants that deliver high ROI for constrained environments.

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com